With several years of experience in the diamond industry, we have developed a unique, in-house grading system for diamonds wholesale that matches the international standards recognized by GIA.

At Sanghvi & Sons every rough diamond in put thought a step by step process, in order to provide optimum output.

At Sanghvi & Sons every rough diamond in put thought a step by step process, in order to provide optimum output.

At Sanghvi & Sons, the entire manufacturing process is based on standardised operating processes that ensure every diamond is subjected to the same high-quality treatment, from rough to polish. Rigid process controls and decades of experience in manufacturing have allowed us to adopt the best practices from other relevant industries.

Our development functions consist of an in-process Excellent Control Division, which utilizes quality manages at every level of development. Our procedure incorporation allows for real-time information selection and reviews which guarantees that the standard quotient is calculated at every point and does not drop below standard stages.

This constant concentrate on quality gives us the capability to provide our customers with the high item quality that we have guaranteed and has led to a number of long-term client connections.

The polishing of the diamond begins; one by one, facets will be ground on to the stone. A facet is the tiny plane or surface that traps the light and makes a diamond sparkle. Most diamond cuts have 58 facets.

The facets are applied to the diamond on a "turntable", made of porous iron, which has been coated with diamond dust and oil. The diamond is set into a holder and held against the turntable as it revolves at a very high speed.

A diamond has been cut well when its facets are clean, sharp, and symmetrical, and the proportions above and below the girdle are correct. A diamond is correctly proportioned when one-third of the total weight of the gem is above the girdle and two thirds below. A well-cut diamond will be fiery, brilliant and beautiful.

The first step for dimaonds wholesale is to carry out sieving to separate the diamonds based on size. The lot is sub divided and the weights are reconciled.

This refers to the process of separating the goods “makeables” (ready for manufacturing) and others which require processing. Goods other than makeables are taken up for marking. In diamonds wholesale industry, this concept does not require any explaination as it is very basic.

This process involves diamond professionals marking the diamond, to explain how it is going to be cut or shaped after which the diamond is sent to the shaping division. Indian diamonds wholesale industry has highly skilled professionals for marking.

Once the diamonds have been sent to the Shaping division, they are sent for Sawing and Cleaving. Cleavable goods are marked for Laser Kerfing. Sawable goods are marked either for Blade Sawing or Laser sawing. Goods are also marked for making “window” to facilitate checking of internals of the diamonds. Shaping is given a great deal of importance as it is crecial to efficient diamonds wholesale.

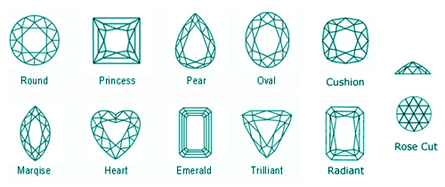

Each diamond has to be cut according to its requirement, and polished to bring out its shine. It is in this process where in the rough diamonds are made perfect. In diamonds wholesale, a great variety of cuts are available and each has its own charm and significance.

Once the diamond has been cut and polished to perfection for diamonds wholesale, it is sent to the Assortment division, where the diamond is assorted according to its cut, carat, colour and clarity. Each assorted packet is given the following identification:

After the diamonds have been assorted they are sent to the quality check division, where they are checked by professionals. Once the diamonds have passed the quality check, they are graded accordingly. Although diamonds wholesale involved processing in large quantities, we make sure that each diamond is thoroughly tested and approved for quality.

After quality check, diamonds go to the grading department. The already faceted diamonds are inspected and fine polished if necessary and then boiled in hydrochloric and sulphuric acids to remove dust, oil and other grit that might mar its shine. The company follows the international standard of grading and makes final packets kapan wise. This is done by some of the most experienced professionals in the diamonds wholesale industry. We follow best standards in diamonds wholesale industry. Sanghvi & Sons has developed its own unique grading system for diamonds that enables the company to provide clients only with the finest products.

Every diamond has its own unique qualities and attributes. Be it a pear shape, oval shape, heart shape, cushion, emerald, escher or radiant, we house the best infrastructure and grading system to every masterpiece manufactured.